The Armory

Indoor track and field at its best.

Build it and they will come

In March of 1985, I was hired to take over the Men's and Women's Track and Field Program at Boston University. It was a huge challenge, as the previous coach was let go, there were funding issues and I was responsible for a program that had just placed 4th at the indoor NCAA Championships on the Men's side of the ledger.

The new Athletic Director, Rick Taylor, had cut the scholarships for the men from 12.6 to 5 full and 6 partials. That meant there would be no scholarships given out over the next few years as graduation and attrition would reduce funding. I was to go out and "beat the bushes" for recruits. With the cost of a Boston University education rivaling those of MIT and Harvard, "finding" recruits was a serious task for certain. Along with that, the Women's program had been short changed and I was also given the task to "equalize" things, providing more opportunities and more funding for the women.

The first thing I did was hire Jan Samuelson, sister in law of Joan Benoit, who had been the woman's coach at BU before I came on board. Jan had an extensive background in coaching, working at the University of Kansas and then running a Special Olympics program in Arizona. She wanted to come back east, close to family in New Hampshire and was willing to take a meager salary to become my assistant. I promised her that she would actually run the show for the women's program, giving her authority over scholarships, budget and all other aspects of the program. It was a good decision.

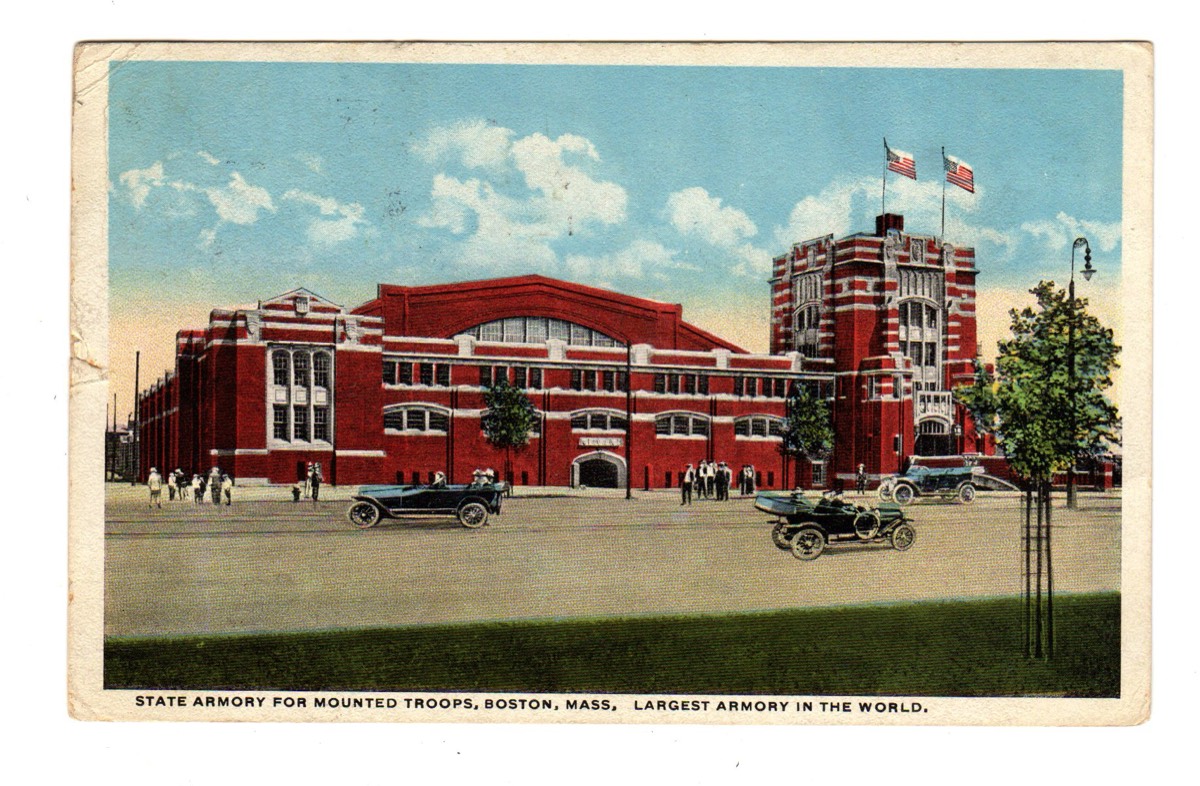

Boston University had an indoor track that was put up and taken down each year. It was located in the Old Armory that was still active for a small group of military personnel. I had not seen the track prior to accepting the job, so my first exposure to it was seeing it stacked up in the back arena about 20 feet high with rain water running over it during rain storms.

In the fall of 1985 Buildings and Grounds was given the task of putting the track together. The process took well over a month as some support boards needed to be replaced and a carpenter was called in for that job. He took over 2 weeks to upgrade the underpinnings. Then it was Thanksgiving and no one worked. The track was finally completed the end of November, a few days before our first indoor meet was to occur.

The track consisted of 180 sections with 2x10 supports running under the straight and triangles for around the turns. It took 6 people to put up the triangle, lift a section and then put up the next triangle for support. It was no easy undertaking.

I discovered that there was a great demand from other track teams to come to Boston and run on our track. The NCAA had qualifying standards and our track, at that time was one of the fastest facilities in the country. In fact, only Harvard, which also had a banked track, had a similar fast track, but they did not allow many schools to compete there.

I received permission to set up the track my second year at the helm. It took me a few years (I set up and took down the track a total of 16 times before we had our new facility built) and finally was able to get the track setup down to a science.

David Callum, one of my sprinter walk-ons loved track and field and wanted to help and, boy, did he ever. He and I were able to get the initial fixing of the 2x4 boards that would invariably break during a season and then we would get the entire team involved in putting the track together.

We set the record of 8.5 hours one year when we had a dedicated crew split into two groups, each working from pieces 1 and 180 up and down to piece 90, the final section that always took some time to get into place. We never were able to get it done that quickly again, but until the last time of putting up the track, the team worked together in unity.

Doing the setup on our own meant we could get inside to do workouts in late October, and anyone that knows the weather in New England, often times it would already be in the high 20's or low 30's by that time.

We hosted anywhere from 7 to 10 meets a season in that old armory. The Terrier Classic used to be the Premier meet of the season, attracting well over 3,000 track and field athletes over a two day period. Our goal was to be on time and produce results to post up on the bulletin boards as quickly as possible. In the early years we used Accutrak, a photo timing system using a Polaroid camera setup. Steve Viatones was very good in being able to get upwards of 8-10 auto times for the distance races, where most operators were lucky to get 4-5. I manned the computer software to correlate results, print them out and post them up. It was a well oiled machine with Tom Meagher being our starter and always on top of his game. David Callum became our clerk and we could run through events almost as well as Penn Relays.

By the time the new track and field facility was built, we were all tired out from the Armory and glad that we would have a permanent track setup. The new facility was outstanding and continues to produce some fantastic performances to this day, almost 20 years later.

The Fall from Grace

Setting up the netting for the weight and shot in the old Armory almost cost me my life.Look out below

I don’t remember the year I almost died setting up the indoor track facility at BU. I think it was 1998, but it could have been a year earlier or a year later. I don’t remember a lot of things after I took this 22 foot fall from the genie while trying to put up the netting for the throwing area, inside the oval. You can see the nets hanging on the right side of the photo above, high up to prevent anyone from getting hit by a shot or weight implement.

The day started out as usual, lots of things to do before starting our indoor workouts at the old armory. I had Building and Groups drill some good sized holes into the infield around the throwing circle and then had 22 foot poles made that would hold up the netting on each side of the circle and across the far end. In years past, Building and Grounds would bring in a truck and a worker would spend a day or two setting up the area. I thought I would be smart and brought over one of

the athletic department genies, used to hang signs, etc. It went up about 18 feet or so and I would then pull up the netting and hang it from the posts, using the attached hooks. The Genie had “feet” that were placed on all four sides to provide stability so it wouldn’t tip. I had about 12 poles that needed to have netting hooked up to them, and moving the Genie from one pole to the next one required taking the support legs off and then putting them on again.

Since I was just going straight up holding the net firmly and then hooking them onto the pole, I saw no reason to use the legs. Silly me.

After I had hooked up netting to four of the poles, I noticed that the netting was hanging a bit low between the poles, due to having too much netting between each pole. I thought I would just pull on the netting and grab some netting a bit closer to the previous pole.

Well, that didn’t quite go so well as the netting pulled back as I was trying to bring the netting higher. The tension was such that not only did the netting pull back, but it tipped the Genie over and down I came. Genie, netting and a screaming coach, yelling”Oh s**t”. That is all I remember.

Fortunately Dan Coval, one of my pole vaulters had come over for practice and was warming up, waiting for me to come over and supervise his vaulting workout. He told me later that after I went down I just lay there “gurgling “. He thought I was dead or dying. He ran as fast as he could to the training room and one of the trainers came over, calling the EMT’s on the way. I woke up in Beth Israel Hospital very early in the morning seeing a very pretty nurse sitting in front of my bed. I knew I had fallen, but that was it. I asked a few questions, including how I was and why she was in the room with me.

The nurse was very kind, explaining she was making sure I was ok and checking to see if and when I would wake up. According to my account, I was out of commission for about 18 hours before waking up. She told me nothing was broken and that I was to just relax and not try and do anything but try and stay awake. I was released later in the day, after Gary Strickler, our Athletic Director stopped by to see how I was.

Needless to say, that was the last time I ever went up on a Genie.

The Track and Tennis Center

Build it - Make it fast

The fastest indoor track in the world

When Jack Parker, the Boston U Men’s Hockey coach demanded that the new track facility be built before the Hockey Arena takes over where the old Armory was located, I thought I had died and gone to heaven. I don’t think I ever thanked Jack for what he did, but I knew, if the new Hockey Arena and Recreation building were to go up first, the new track facility would become nothing more than dream and a promise unfulfilled.

The second miracle that came about with the building of the new track is that I was allowed to have input in the design and build. Bruce Lehane, my assistant coach, and I knew a bit about tracks. His point of view was towards the distance events, while mine was towards speed and spectator interaction. Fortunately, we both got to contribute quite a bit to the project.

Our first meeting with the Architects (Cannon) was interesting to say the least. This group had built the Reggie Lewis Center, a great facility for high schools, but it had some major issues that we all knew about. At that first meeting, the Cannon Group came with their Reggie Lewis drawings and suggested building a similar facility. I stood up and stated that I had a better idea and if they were going to go with the Lewis plan, I didn’t want to be part of the group.

Fortunately, I didn’t offend too many in the group, particularly the BU administration contingent and Cannon took their plan and put it away, asking me for my input. I described how I envisioned a facility that was not only fast and permanent (as 16 years of putting up and taking down the old Armory track was no fun), but was also spectator friendly. I also suggested in a firm voice the need for the track to be made of wood supports and not steel, as most new indoor tracks were being constructed. Mondo had the indoor track construction business pretty much to themselves, so trying to introduce a different contractor was not an easy sell.

My vision of the track was that it be sunk down a bit, with the stands having great sight lines to the track and infield. I wanted to have the throwing cage outside the oval, similar to how Harvard had theirs and Bruce wanted a flat jogging lane outside of the oval.

Since tennis courts were also to be included in the facility, the long jump and triple jump pits had to be outside of the oval, on the far side, away from the stands.

Slowly and surely, the design started to take shape. There were limits to how much could be done, since the footprint for the building was restricted by railroad tracks in back of the property. Thus, there was no availability for having seating on the far side of the oval.

The home stand design was accepted and applauded as it then made it possible to have bathrooms, locker rooms and storage underneath the stands, and provided excellent sight lines. Seating was set back a bit, due to having an aisle in front for wheelchair access, but by putting a glass railing to prevent people from falling onto the track, viewing of the races was excellent.

I also asked for a dedicated weight room to finish off the project.

Bruce and I located Floyd Highfill, who had built a number of very fast tracks back in the 1980’s-1990’s using plywood instead of pine boards. Floyd was semi-retired, but came East to build the BU track for us. They key element for the track was that it have wood supports, that it would be permanent and Floyd also proposed that the banks be asymmetrical, so that one would reach the peak of the turn prior to the middle of the turn. The final discussion was on the height of the track. Our old track was a four lane monstrosity that was 5 feet at the peak. Harvard’s banks were 36 inches, while the Reggie Lewis bank was 24 inches. Floyd had suggested 48 inches, which I thought was ideal, but Bruce, advocating for the distance runners and women wanted something a bit lower. The compromise was 38 inches, just a bit more of a bank than Harvard.

The project itself took quite some time, during a time when I was getting remarried and my father in law was dying. I made numerous trips back and forth between Delaware, Ohio, where our in-laws lived and Boston, overseeing the installation of the track.

We ran into a few problems, including the concrete layer that was to support the track was not even. Shims were needed to make things level. Meanwhile the wiring for the Lynx timing system had also been done incorrectly with junction boxes and wires being omitted from a few locations. That also was fixed.

The initial sound system never worked properly and had to be replaced at the tune of an extra million dollars. Finally, Tennis wanted privacy when they were practicing on the infield, requiring netting that one could not see through. I proposed a two tier netting system, where most of the netting was solid, with a 10 foot “see through” netting attached at the bottom. This setup would enable the track team to use the track while others used the infield (recreation used the facility for two years before their building was finally put up)as the solid netting would be raised 10 feet. During tennis practice, the solid netting was brought down to the floor and tennis would have their privacy. We could still practice, but we could not see the runners on the far side of the track. When track meets occurred, all the netting was raised above the arena, suspended from metal rods around the entire oval.

Early on, the motors that controlled the lowering and raising of the netting sometimes malfunctioned or broke down, so it took some time to come up with motors strong enough to lift the netting. The netting design was created by a local company that specialized in fishing netting and found the challenge to their liking. I believe the Boston University netting system is unique, as I have never seen another system like it.

Now in its 23rd year of operation, the Dodge Physical Fitness Center has become a Mecca for track and field competition, attracting some of the best athletes in the world to compete and set world, country, school and personal records on a super facility that has been proclaimed the fastest indoor track in the world.

Return to America page